When asked about what we do at Freya, I often boil it down to, “We predict the future.” This regularly results in a conversation about the complexities of the work that we do. This can be true, but whenever possible I take the time to remind people that with just a little effort, they can produce some key insights into their own world.

Key insights based on historic (‘descriptive’) data can help you improve your business. Good predictions based upon accurate (‘predictive’) models can help you take it to a whole other level.

So, when do you need to engage some outside help to upgrade to prediction?

In this article, we’ll outline what the stages of data analytics are, at which stage it is worth considering engaging a data analytics team and the benefits of doing so.

In particular we’ll focus on graduating from descriptive to predictive analytics.

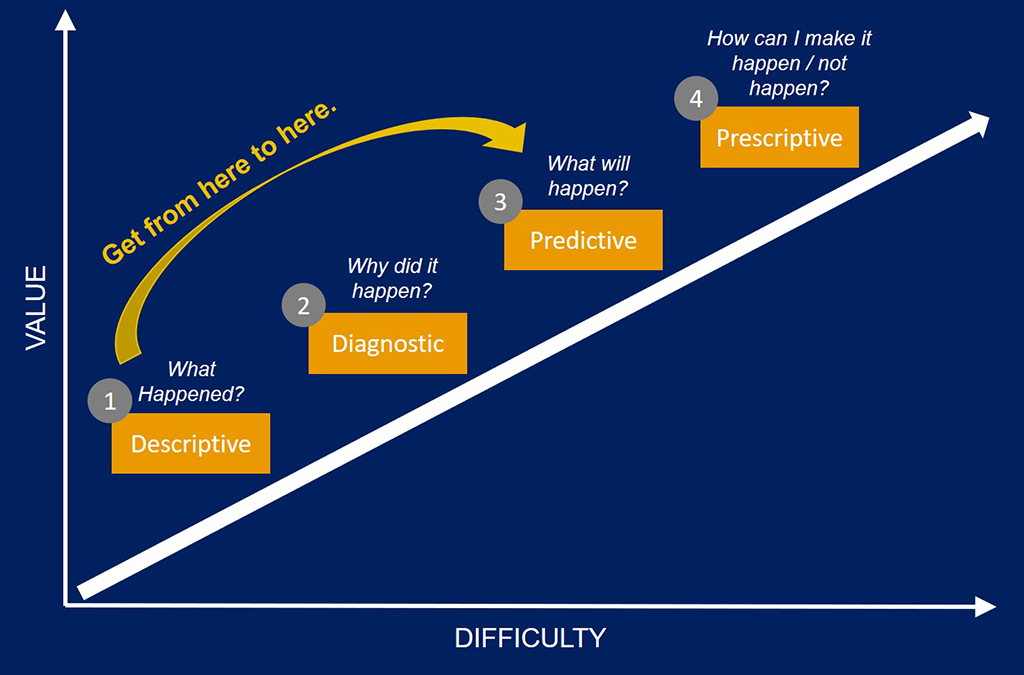

The Four Stages of Analytics

Each Provide Different Benefits

- Descriptive – This is the simplest stage of analytics in which historic data is analyzed to identify ‘what happened.’ Events of interest can be identified and the data can be aggregated to identify the events that occur the most.

Example: The engine warning light has illuminated on the dashboard of a car. We could use the historic data for the use of the car, where driven, for how long, any maintenance that has been recently performed and create views (charts and graphs) of the information to show what happened to the car leading up to the point the light came on.

- Diagnostic – At this stage deeper levels of analysis are required, usually involving subject matter experts in the domain. This is so we can determine ‘why it happened’ or the root-cause of an event or failure.

Example: We can use the historic data mixed with domain experience to identify what has caused the engine warning light to come on. This could be automated into a message to state the cause of failure to the driver.

- Predictive – In this stage the complexity jumps. In order to predict future events, mathematical models are required. These require multiple iterations of development. This is in turn followed by refinement and testing to get the models to the required level of accuracy, which is dependent on the needs of the customer.

Example: We can use batches or a continuous feed of data from the car to predict the next time the engine warning light is going to come on. This could result in a message to the driver to tell them to take their car to a mechanic within a number of miles.

- Prescriptive – At this stage we develop complex models of a device or system and its sub-components. The resultant model will provide insight into all favorable outcomes and suggest courses of action by which they can be achieved.

Example: We can use batches or a continuous feed of data from the car to recommend the maintenance or part replacements that should be made to prevent the engine warning light from coming on.

Although the stages illustrated above seem like a progression, moving from one stage to the next, this is not strictly true. It is entirely possible to jump straight to a prediction of events without knowledge of why they occur. However, the data gathered at the descriptive stage is still required as a basis for modeling.

Most companies are already performing some level of descriptive analytics where the biggest hurdle is usually gathering all of the available data. Following that aggregation, trending and visualizations of the data can be conducted in tools such as Microsoft Excel or Tableau.

The Diagnostic Stage

The diagnostic stage benefits greatly from the input of subject matter experts – those people in a team or organization who understand the domain and processes the best. As noted earlier, the diagnostic stage focuses on identifying the root cause of the problem. This is the stage where crossover to an external analytics team often delivers good results. Data scientists and analysts can work in partnership with these experts who have the skills and experience to label results as failure or non-failure ensuring that end conclusions align with the real-world. The data scientists are likely to be able to utilize the relationships between key contributors and the identified issues to construct an algorithm and warn users of the data when an issue is likely to occur. Automated algorithms such as these will save subject matter experts from the mundane repetitive tasks. This allows them to do what they do best, refining processes and working on the next complex issue requiring diagnosis.

The Predictive Stage

Moving into the predictive stage is where an experienced analytics company can really help. Predictive analytics requires the development of a number of models which also have to be thoroughly tested for performance and accuracy. This requires numerous iterations to find the best fit of models for the prediction scenario. An analytics company will use their experience to narrow down the best combination of potential models, quickly and efficiently. They will also balance the project needs based upon: result accuracy, timescale and available funding. Additional factors that need to be considered for developing an algorithm for the project: sensitivity (e.g. do we need to predict a problem in the next 1, 100 or 1000 miles), complexity, and reporting. In many cases they will also have a toolkit of previously developed code and algorithms that can be adapted to efficiently fit new scenarios.

They will also work tightly with your subject matter experts to validate the important factors of models developed. Often predictive models can be developed and used immediately without a root cause ever being established. The benefits of predictive analytics for fleet and manufacturing lines are:

- A reduction of unforeseen downtime from equipment failures which also results in a reduction of corrective maintenance.

- A reduction in schedule risk, as unscheduled downtime is reduced the impact on the schedule is also reduced, which in turn improves the confidence of execution to the schedule.

- Improved part stock management, less parts need to be kept on hand in case of failure and ultimately part lives can be extended.

- Improved effectivity of maintenance that reduces cost, as more maintenance is moved from corrective to preventative it can be better managed and optimized.

- Process and performance optimization, with greater levels of uptime, contingency can be reduced, which maximizes the use of the equipment and ultimately increases productivity.

- Improved operator safety, the reduction in failures includes destructive failures which could result in personal injury or death.

Much as we would wish to tell you the opposite, no model is perfect. The right model can be used to generate predictions which are rooted in data, to known levels of confidence. This quantifies the uncertainty for the consumer, resulting in higher quality decisions. Data scientists will also ensure that the story of the data and predictions based on it is told in a way that is easily understood by the consumer.

A good data science team will help you make this transition from looking into the past to looking into the future.

Call today to find out how we can do this for you.