Freya System Solutions

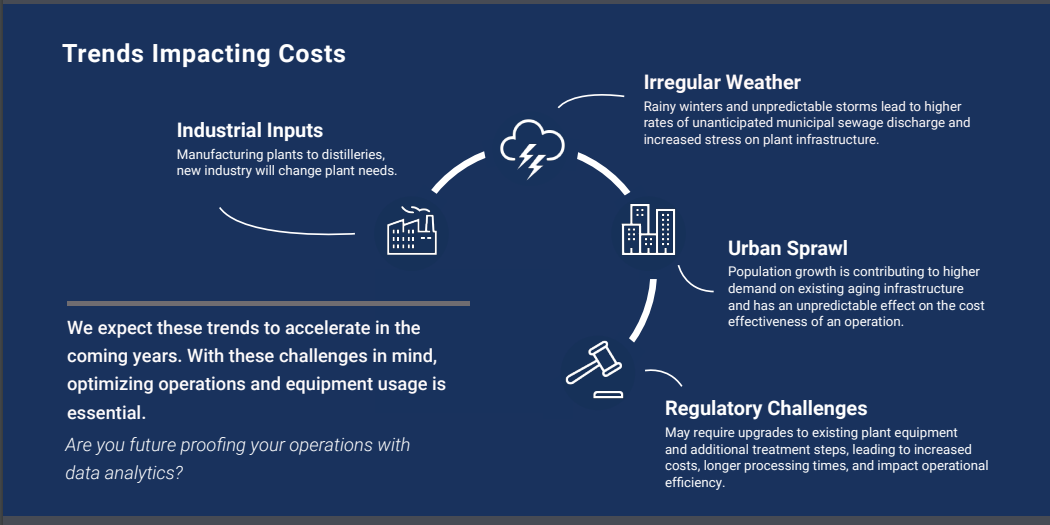

Freya Systems steps forward as your collaborative data science ally, positioning both operations and the executive offices to redefine industry standards for asset management in utilities. Our role is to catalyze a leap in operational excellence, where expectations for efficiency, cost-effectiveness, and environmental sustainability are not just met—they are surpassed.

By infusing your asset management strategy with our data-driven insights, your team benefits from improved clarity and control over your utility’s performance. We work closely with your personnel, instilling a data-centric approach that turns every challenge into an opportunity for optimization and every decision into a stride toward progress.

For Operations, this partnership transforms the power of existing systems by leveraging your data with technical expertise in AI-algorithms and predictive analytics tools.

For Executives, it means navigating the future of utility asset management with a compass of concrete data, charting a course that promotes fiscal prudence and a legacy of sustainability. Freya Systems has proved they can save 5% of the annual energy consumption for a utility, learn more.

See a real-life case study highlighting how we saved a wastewater treatment plant 5% of their annual kW usage.

Predictive Algorithm Engineering

Advance your utility asset management with predictive algorithms that identify potential system failures and prescribe maintenance schedules. This foresight enables decision-makers to allocate resources more effectively and often proactively, ensuring operational continuity and financial prudence.

Data Engineering and Operational Optimizations

We don’t just analyze data; we engineer it. Our data engineering services lay the foundation for robust analytics, creating a streamlined data ecosystem that supports operational excellence. With these insights, engineers can refine processes, and executives can make informed decisions that lead to optimized performance and sustainability.

Advanced Anomaly Detection

Our advanced anomaly detection capabilities allow for real-time monitoring of your systems. Engineers gain a vigilant watchguard, spotting and diagnosing irregularities instantaneously, while executives are equipped with the knowledge to mitigate risks and uphold compliance standards.

Strategic Consultancy Services

At Freya Systems, we offer more than the latest in AI data analytics and utility asset management solutions; we deliver the experience required to master the intricacies of data and asset management. Our consultancy expertise enhances your strategic initiatives, providing comprehensive insights and detailed guidance crucial for your utility. Our goal is to steer your enterprise toward a cohesive AI and advanced analytics strategy that integrates effortlessly with your broader company goals.

Your Advantage with Freya Systems

Detailed report that captures study findings, including data quality assessment, potential project assessment, conclusions, recommendations, etc.

Detailed report that captures study findings, including data quality assessment, potential project assessment, conclusions, recommendations, etc. Executive-level presentation highlighting important study findings.

Executive-level presentation highlighting important study findings. Estimated ROI for potential projects.

Estimated ROI for potential projects.