The DoD’s Underperforming Aircraft Mission Capability Rates

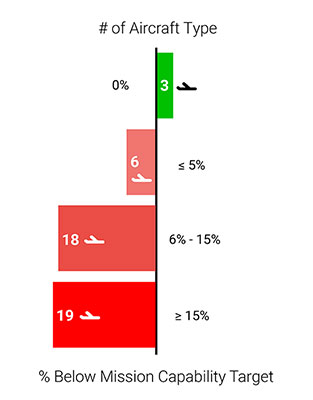

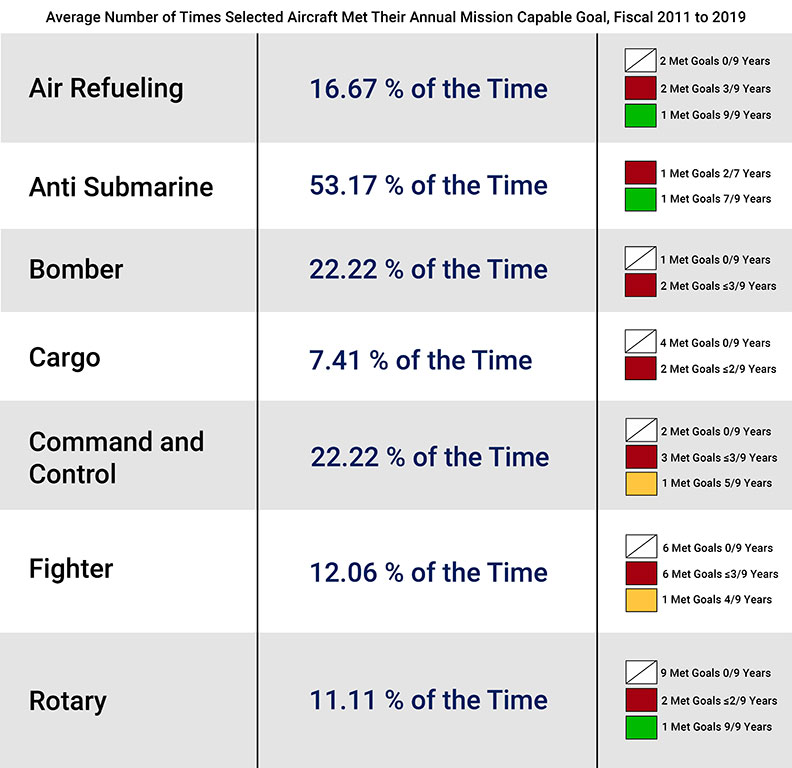

From a glance, the US Military’s aircraft mission capability rates are underperforming across the board. A Government report released in November of 2020, reviewed 46 aircraft systems and found that only three met their annual mission capable targets in the majority of years from 2011 to 2019. Twenty-four did not meet their annual mission capable goals in any of those years. This can be primarily attributed to aging aircraft, unscheduled downtime and delayed maintenance, a shrinking workforce, and supply shortages for legacy aircraft, among others.

Tackling these underperforming mission capability rates requires advanced digital integration, from predictive and preventive analytics, and customized data-driven software tools, to improved ERP processes. Implementing a bespoke set of digital solutions for ground operators, maintenance personnel and management will give the insight and clarity to plan more thoroughly and help achieve the military’s mission capability goals.

Visualizing the Problem

In aggregate, the average mission capable rate has trended lower for the sampled Air Force, Navy, and Marine Corps aircraft since 2011, while Army aircraft showed minor improvement.

In 2019, the Government Accountability Office found that only three out of 46 aircraft systems met the service-established mission capable goal.

Visualization of this readiness deficit by aircraft (2011-2019) taken from the Government Accountability Office report GAO-21-101SP can be seen in figure 2 below.

Identifying the Challenges Causing Low Readiness Rates

Efficient sustainment of fleets is a logistical, operational, and MRO challenge for defense personnel. Below we have summarized the primary challenges causing the low aircraft mission capable rates.

Aging Aircraft

1. Unexpected replacement of parts and repairs

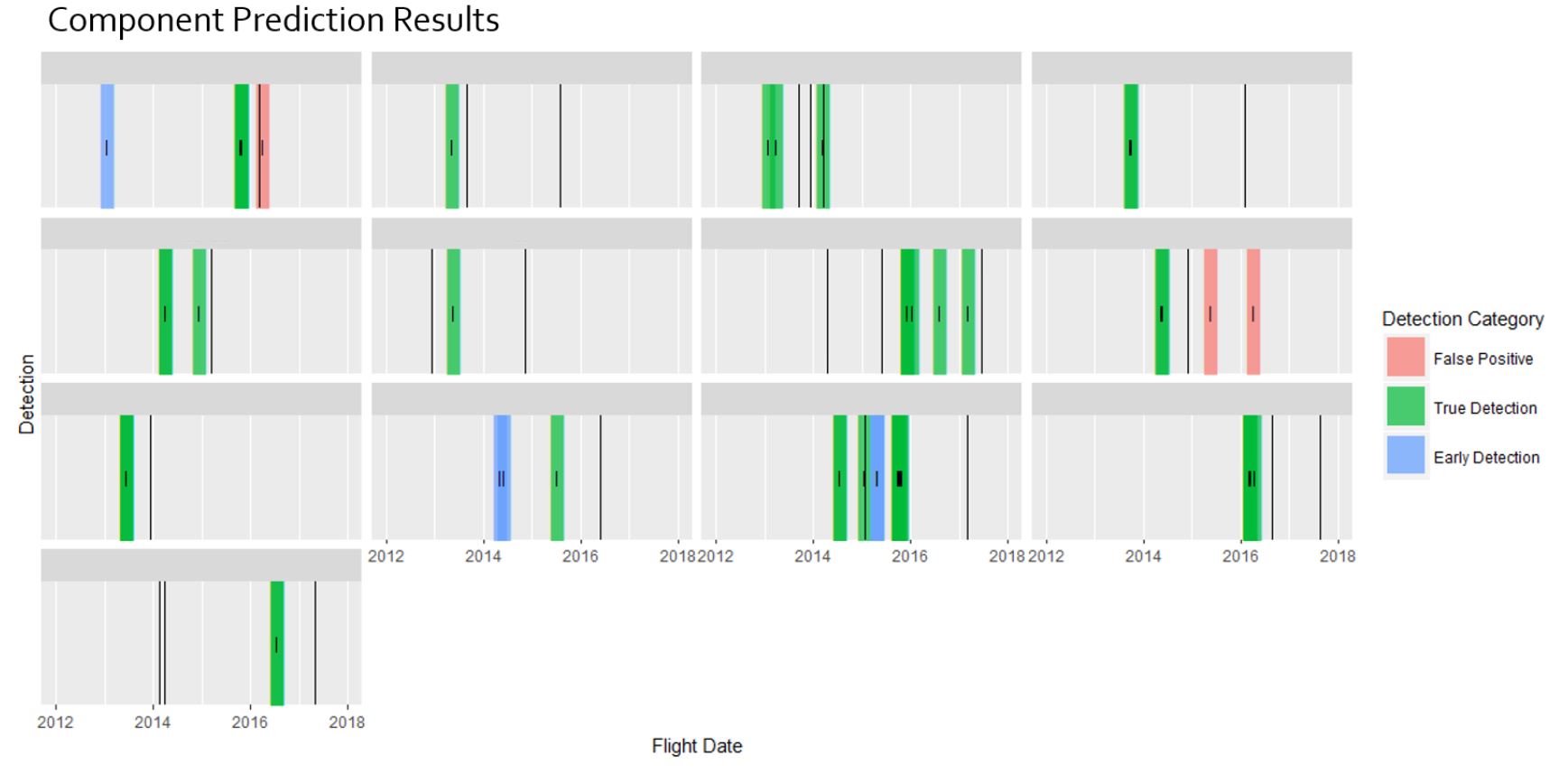

Predictive analytics tools can be integrated into existing maintenance and supply chain support systems to accurately forecast equipment failure and health, based on real world variables and historic data. Anomaly detection algorithms reduce the chance of an unpredicted component failure by predicting and notifying decision makers of any potential data points outside normal operating behavior.

2. Service life extensions

With the advent of predictive maintenance and advanced sensor data links, information can be used to foretell and prevent component breakdowns on aircraft, extending its service life. Algorithms can be used to analyze aircraft component behavior to determine their probability of failure.

Maintenance

1. Unscheduled maintenance

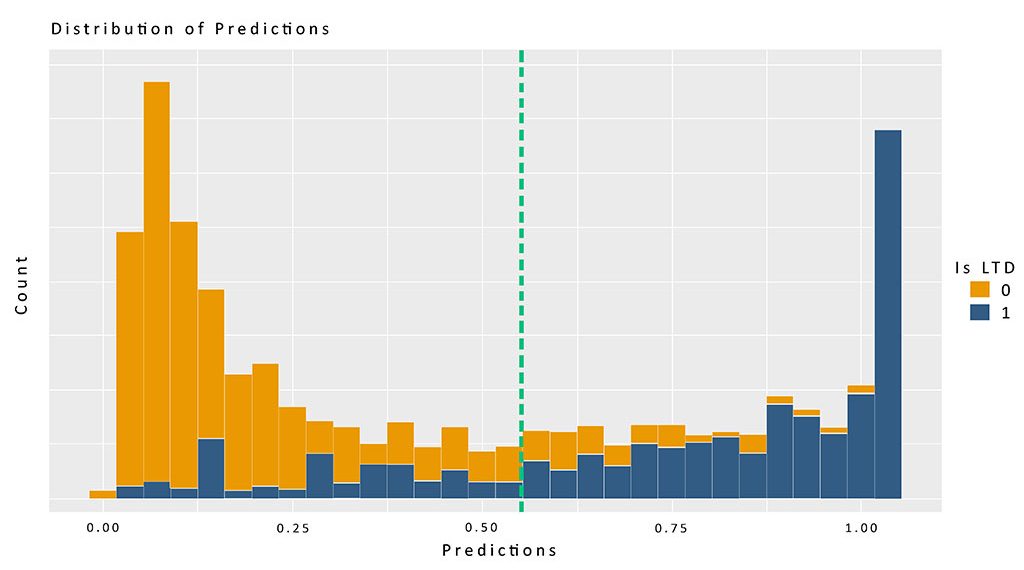

Unscheduled maintenance can now be heavily mitigated; utilizing AI and machine learning, predictive and preventative maintenance algorithms can take historic data and identify future maintenance and supply needs. Military operators need to move from a reactionary parts procurement system to a predictive one. In addition to predicting component failure, this process can enable a condition-based maintenance approach in which maintenance intervals are based on real time aircraft diagnostic data rather than uniform predetermined schedules. These tools can help fleet managers take a glimpse into the future and determine to what extent an aircraft will require maintenance and when they are likely to reach a Long Term Down state.

2. Delays in depot maintenance

Depots vary in efficiency by location and by military branch, however, improved parts inventory management and integrated advanced fleet management tools can aid maintenance workers in an increasingly digitalized environment. The US Airforce completed maintenance on time or early for 5 out of 6 years on selected fixed wing aircraft from 2014 to 2019, while the US Navy depots completed maintenance late each of the 6 years, according to the GAO-20-390 report. The Navy’s fixed wing aircraft have spent 62,000 more days in maintenance since 2014. (GAO-20-390) Depot maintenance typically takes longer when performing periodic maintenance intervals, and with the Navy’s attention primarily on aircraft carriers, landlocked aircraft receive less attention.

The disparity in depot maintenance speed and readiness can be attributed to the Air Force’s increased planning, forecasting, and predictive modeling resources. While both branches have initiatives underway to curb these slow maintenance times, GAO has recognized that the Navy needs to address certain planning challenges. The Navy needs improved use of historical data analysis and predictive forecasting to establish accurate scheduling targets and coordination. Navy maintenance depot operators need improved visibility of aircraft status and condition outside their domain. The Navy also requires a formal set of processes for guidance and coordination between key depot stakeholders to allow for improved communication.

3. Shortage of trained maintenance personnel

The shortage of qualified maintenance personnel in the industry means that military operators need to not only encourage and train new candidates to fill these roles but also need to make sure that their existing personnel are operating as efficiently as possible. With the aid of data-driven insights, predictive modeling, and digital solutions, maintenance personnel can spend less time doing menial tasks, and more time adding meaningful value to the fleet.

Supply Support

1. Parts shortage and delay

Parts-inventory management relies on a host of web applications and ERP systems that link data between MRO crews, operators, supply chain managers, and flight crews. With the advent of IoT (Internet of things), smaller, smarter uses of sensors, RFID tracking, and bar code scanning can be used to more effectively track existing inventory and allocate better in advance. Streamlining data processes and advanced supply chain forecasting can reduce parts shortages and delays.

2. Diminishing manufacturing source

Legacy aircraft systems are challenged with diminishing original equipment manufacturer supply infrastructure. Older aircraft fleets receive more limited support and slower response times from suppliers. Given that most suppliers are the sole source, there is limited to no supplier competition and buyer power. To counteract diminishing supply infrastructure, operators can prepare in advance and purchase aging support equipment and parts in bulk.

3. Parts obsolescence

As equipment becomes older, so do the parts that support it. Obsolescent parts include components that are no longer maintained, manufactured, or have become degraded. Identifying obsolescent parts as early as possible allows for a wider range of solutions.

The department of defense spent approximately $49 billion on operating and support (O&S) costs in the 2018 fiscal year based on 46 fixed and rotary wing aircraft in the departments of the Army, Navy, and Air Force. Operations and support maintenance costs vary per aircraft type, with the size of the fleet, maintenance difficulty, and status of manufacturing source being contributing factors.

Machine Learning and Predictive Analytics: The Golden Ticket?

A reoccurring theme within the problems causing low defense mission capability rates is the inability to successfully forecast future maintenance and parts-inventory needs. Incorporating predictive and preventative analytics capabilities into new or existing data systems can provide a solution to the low mission capability rates seen across military platforms. Implementing these changes requires a great deal of expertise, and so partnering with a competent team that has the right analytical expertise and domain knowledge is paramount.

These solutions can be implemented and drive serious change for military and commercial applications. Freya Systems enabled a leading Aerospace customer to increase a military contractor’s fleet availability and readiness by over 8%, stopping 26 aircraft from becoming Long Term Down. To improve the analysis of component data, Freya Systems developed a web application for flight operators that streamlined part data and other variables to allow for critical decision support and reduced time and cost expenditure. The final application allowed aircraft operators to save greater than $500K in annual savings, forecasted to increase to over $3.5M annually when expanded to the full fleet. Implementing these solutions into an existing platform would allow the end customer to save significantly and add tremendous value to existing data systems and decision makers.