Maximizing Biogas Utilization: A Story of Sustainable Innovation in Wastewater Treatment

Background

A municipal wastewater treatment facility sought to enhance sustainability through greater reliance on biogas and solar power. While they captured and used biogas for energy, contractual restrictions prevented selling surplus energy back to the grid—leading to frequent flaring of excess biogas and lost potential. This situation not only increased greenhouse gas emissions but also conflicted with the facility’s environmental goals.

Flaring not only wastes a valuable resource but also increases greenhouse gas emissions. The plant’s leadership was committed to reducing reliance on natural gas, maximizing biogas utilization, and addressing inefficiencies. Achieving these goals requires a data-driven solution that would clarify energy production patterns and inform operational improvements.

Key Challenges

Excess Biogas Flaring

Reducing Reliance on Natural Gas

Data Fragmentation

Staff Knowledge Transfer

Senior operators with crucial operational insights were nearing retirement, creating a need for improved data transparency and intuitive reporting for incoming staff.

Solutions

Freya Systems approached the facility’s challenges with its hallmark method: digging deep into data while collaborating closely with the operations team. The process began with a thorough assessment of the facility’s existing data architecture, identifying gaps and inefficiencies. Freya’s team worked alongside plant engineers to ensure that the solution addressed both operational goals and broader business objectives.

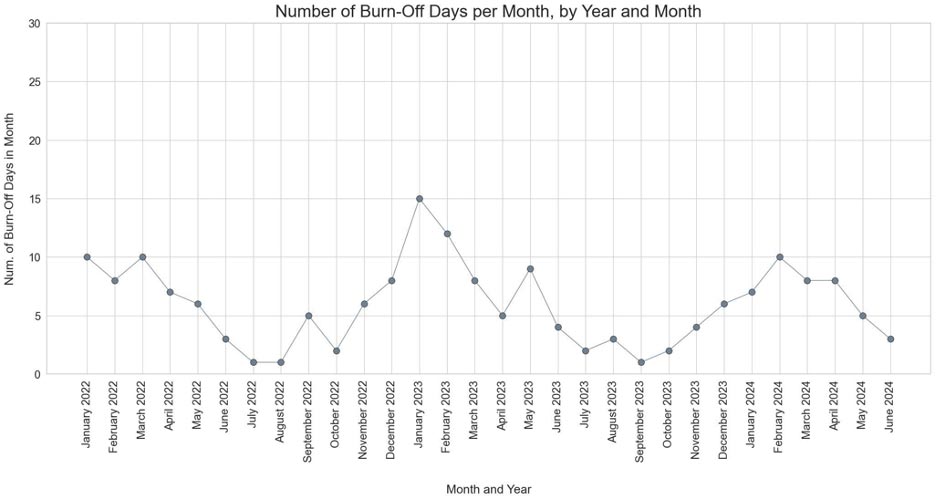

Data Integration and Analysis Freya aggregated and analyzed data from various operational systems, focusing on biogas production, natural gas usage, and flaring events. Statistical methods were applied to uncover patterns in energy production, identifying times when excess biogas was being flared unnecessarily.

User-friendly visualizations were developed to analyze energy production patterns. This tool synthesized complex datasets into actionable insights, giving operators a clear view of biogas utilization rates, flaring frequency, and energy efficiency metrics.

By working closely with the facility’s operations team, Freya ensured that the data analysis aligned with real-world workflows. This collaborative approach enabled engineers and operators to apply insights effectively, creating a roadmap for improving energy efficiency.

Detailed analytics provides a foundation for advanced AI/ML solutions to further enhance energy efficiency and operational performance.

Outcome

- Minimize biogas flaring by adjusting operational schedules.

- Optimize the ratio of biogas to natural gas in energy production.

- Reduce energy waste, aligning with sustainability goals.

The benefits extend beyond the facility’s walls. By reducing flaring, the plant would significantly decrease greenhouse gas emissions, contributing to cleaner air for the surrounding community. Moreover, the cost savings from improved energy efficiency would bolster the facility’s budget, enabling reinvestment in other projects.

This project also had a ripple effect on workforce development. The structured data and intuitive visualizations provided a foundation for knowledge transfer, empowering the next generation of operators to make informed decisions based on clear, reliable data.

Analysis revealed significant cost savings opportunities, such as reducing unnecessary flaring events, potentially saving hundreds of thousands of dollars annually.

Next Steps

Freya Systems and the wastewater treatment facility continue to refine capabilities, exploring advanced analytics and machine learning applications to further enhance operations. This partnership underscores the value of data as a strategic asset, paving the way for smarter wastewater management.